Mestract, the leading cosmetics manufacturer in domestic market, has strictly implemented the GMP and ISO22716 Cosmetics Good Manufacturing Practices for production workshop and environment, and passed the certifications of ISO9001 Quality Management Systems and ISO14001 Environment Management Systems and OHSAS18001 Occupational Health Safety Systems.

The design ideas for division of people and materials flows was adopted for workshop to ensure the safe, rational and humanized environment for production. The laboratory room, emulsification workshop, filling workshop, storage room for semi-finished product, material-preparation room, disinfection and storage room for inner packaging materials and clothes-changing room have adopted the 100,000 grade air-purifying standards, other area introduced the 300,000 grade air-purifying standards, which can remove the 99.97% of bacteria and dust in air and ensure that all products can be manufactured and filled and packed in safe, non-polluted environment.

The MFS (METTLER-TOLEDO) Batching and Manufacturing Management System was introduced to enable production department to arrange the production, control quality, finish the statements and report, transmit the processes by the system every day. This is a complete set of system which can be examined by long time, huge output and high efficiency.

The popular application of leading Mettler-Toledo weighing system in the industry can guarantee the accuracy of 0.001% gram in the test and weighing.

The management from the incoming and outgoing raw materials into warehouse to emulsification and production, and from the filling of products to the storage of finished products will be shown on the screen which was integrated with MES system, SAP system, and on-site controller (PLC).

On basis of fully-automated information emulsification, the data chain of production process has been created to guarantee the real-time monitoring, processes storage, and data-tracking, etc. production process information.

The supervisory management in production process and traceability of product quality have been improved to meet the needs and demands of modernized scale production.

Full clean pipeline, storage tank, and two-grade reverse osmosis modules made of 8080 big membrane from USA DOW were introduced, the EDI membrane stack was used from Simens, which has automatic cleaning function.

The whole machine was controlled by Simens PLC, and can automatically monitor the water quality value, and automatically condition and regulate the Ph value of water quality.

All storage tanks have been equipped with immersing bacteria-disinfecting system, and final water output entrance has been equipped with filtering bacteria-disinfecting system to guarantee the water quality.

Extra-pure water conductivity is lower to 0.06μs/cm (general water conductivity is 4-5μs/cm in the industry).

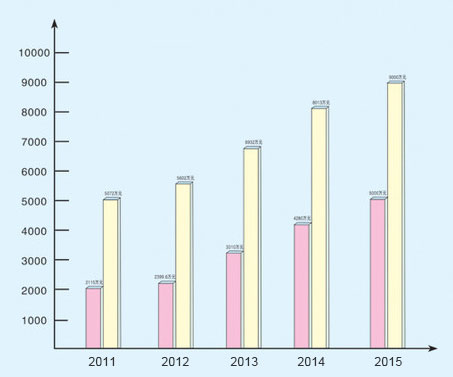

Mestract, at present, has closely cooperated with many famous brands and daily chemical chain brands in domestic market, established excellent cooperative relationship. Mestract has powerful production capacity ourselves, and can completely meet the requirements of production capacity by first line brand in domestic market.

1

Equipped with automated production facilities for 12 lines.

2Average production capacity of facial mask can reach 500000 sheets every day, and the ointment and cream products can be produced daily for 300000 pieces, with annual output of 93.60 million pieces.

Filling and Packing Facilities

To enhance the packing efficiency of products with soft tube packing, and easy to operate for workers.

Fully-automated water and emulsion and cream filling machine

It can be fully automated to fill the products, and it is accurate, safe, high-efficient, of permanent output,and the whole processes can be controlled.

Facial Mask Filling Machine

It is exclusive for facial mask to fill essential liquid, and its sealing mouth is beautiful and the filling is accurate and safe.

Fully-automated clear film packing machine

Fully-automated intelligentized outer packing can optimize product appearance and enhance the visual attraction of product.